Eliyahu M. Goldratt – Theory of Constraints

Eliyahu M. Goldratt – Theory of Constraints – Contents

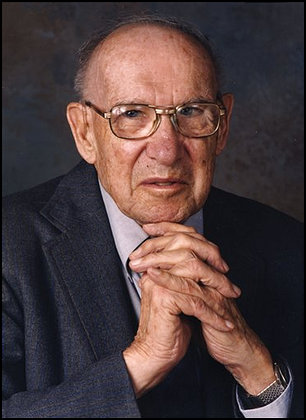

- Eliyahu M. GoldrattDeming Biography

- Eliyahu M. Goldratt – Big Ideas:

- Theory of Constraints (TOC)

- Interesting Facts and Insights about Eliyahu M. Goldratt

- Career Advice Quotes by Eliyahu M. Goldratt

- Business Advice Quotes by Eliyahu M. Goldratt

- Leadership and Management Advice Quotes by Eliyahu M. Goldratt

- Eliyahu M. Goldratt – Production Advice Quotes

- Eliyahu M. Goldratt Inspirational Quotes

- Books by Eliyahu M. Goldratt

- Books about Theory of Constraints (TOC)

- Questions about Eliyahu M. Goldratt

- Eliyahu M. Goldratt– Videos

Eliyahu M. Goldratt – Biography

Eliyahu Moshe Goldratt (1947 – 2011) was a business management guru. He was the originator of the Theory of Constraints (TOC) and other Production and Process TOC derived tools. The Theory of Constraints (TOC) is a management philosophy introduced by Goldratt in his book titled “The Goal.”

Goldratt was the author of several business novels and non-fiction works, mainly on the application of the theory of constraints to various manufacturing and business processes. Time Magazine listed his book “The Goal” as one of “The 25 Most Influential Business Management Books.

Eliyahu M. Goldratt – Big Ideas:

Theory of Constraints (TOC)

The theory of constraints (TOC) is a management paradigm that views any manageable system as being limited in achieving higher goals by a minimal number of constraints. There is always at least one constraint, and TOC uses a focusing process to identify the constraint and restructure the rest of the organization around it.

TOC adopts the idiom, “a chain is no stronger than its weakest link.” This means that processes and organizations are vulnerable because the weakest person or part can always adversely affect the outcome. Eliyahu M. Goldratt introduced TOC in his 1984 book titled “The Goal.” Goldratt adapted the concept to project management with his book “Critical Chain,” published in 1997.

The underlying premise of the theory of constraints is that organizations can be measured and controlled by variations on three measures: throughput, operational expense, and inventory. Before the goal itself can be reached, safety, quality, legal obligations, and other the necessary conditions must first be met.

Constraints

A constraint is anything that prevents the system from achieving its goal. Constraints can be internal or external to the system.

An internal constraint is in evidence when the market demands more from the system than it can deliver. The focus of the organization should be on discovering that constraint and remove it.

Types of Internal constraints include:

- Equipment: The way equipment is used limits the ability of the system to produce more.

- People: Lack of skilled people limits the system. Mental models can also cause behaviors that become a constraint.

- Policy: An unecessary policy that prevents the system from making more.

In TOC, the constraint is used as a focusing mechanism for the management of the system. The constraint is the limiting factor that is preventing the organization from getting more throughput typically, revenue through sales.

An external constraint exists when the system can produce more than the market will bear. If this is the case, then the organization should focus on mechanisms to create more demand for its products or services.

The Five Focusing Steps

The five focusing steps aim to ensure ongoing improvement efforts are centered on the organization’s constraints. This is referred to as the process of continuous improvement (POOGI). Assuming the goal of a system has been articulated and its measurements defined, the steps are:

- Identify the system’s constraints.

- Decide how to exploit the system’s constraints.

- Subordinate everything else to the above decisions.

- Alleviate the system’s constraints.

- If, in the previous steps, a constraint has been fixed. Start again on the nest constraint.

These process of ongoing improvement, have been applied to manufacturing, project management, supply chain/distribution generated solutions. Other tools, mainly the “Thinking Process” has also led to TOC applications in the fields of marketing and sales and finance.

Thinking Processes

The “Thinking Processes” are a set of tools to help managers walk through the steps of initiating and implementing a project. They help achieve a buy-in process:

- Gain agreement on the problem

- Gain agreement on the direction for a solution

- Gain agreement that the solution solves the problem

- Agree to overcome any potential negative ramifications

- Agree to overcome any obstacles to implementation

TOC practitioners sometimes refer to these as working through “layers of resistance” to a change.

Interesting Facts and Insights about Eliyahu M. Goldratt

- Born: Eliyahu Moshe Goldratt was born in 1947, in Mandatory Palestine.

- Family: Goldratt was born into a rabbinic family, one year before Israel’s modern statehood.

- Father: Goldratt’s father was Avraham-Yehuda Goldratt. He was an Israeli journalist and politician who served as a member of the first Knesset between 1949 and 1951.

- Degree: Eliyahu M. Goldratt obtained a BSc degree from Tel Aviv University.

- Masters and Ph.D.: Goldratt achieved his MSc and Ph.D. degrees from Bar-Ilan University in Ramat Gan, Israel.

- Creative Output: Goldratt joined Creative Output. The company developed Optimized Production Technology (OPT) software. The software provides capacity scheduling for production environments.

- Controversies: Goldratt was involved in controversies such as Cost Accounting v Throughput Accounting, which led him to co-write “A Town Without Walls” Whitepaper, distributed during APICS 1984 International Conference in the USA.

- Author: Eliyahu M. Goldratt was the author of several business novels and non-fiction works, mainly on the application of the theory of constraints to various manufacturing, engineering, and other business processes.

- Originator: Goldratt was the originator of the Optimized Production Technique, the Theory of Constraints (TOC), the Thinking Processes, Drum-Buffer-Rope, Critical Chain Project Management (CCPM), and other TOC derived tools.

- The Goal: “The Goal” is a management-oriented novel by Goldratt, initially published in 1984. The book is used for case studies in operations management, with a focus geared towards the theory of constraints, bottlenecks, and how to alleviate them.

- Recognition: Time Magazine listed the book “The Goal” as one of “The 25 Most Influential Business Management Books.

- Avraham Y. Goldratt Institute: In 1985, Goldratt created the Avraham Y Goldratt Institute (AGI), named after his father, to promote the Theory of Constraints and help it be implemented worldwide.

- TOC: During the time of the AGI, Goldratt further development of his TOC practice, mainly the Thinking Processes, Critical Chain Project Management, and other applications.

- Influence: Goldratt concepts influenced applications outside manufacturing and supply management, including the field of sales process engineering.

- Died: Eliyahu M. Goldratt died in 2011, aged 64, in Israel.

Career Advice Quotes by Eliyahu M. Goldratt

“Bringing a company closer to its goal. Every action that brings a company closer to its goal is productive.”

“Never let something important become urgent.”

“Tell me how you measure me, and I will tell you how I will behave.”

“An hour saved at the non-bottleneck is a mirage.”

“To avoid feeling disappointed, one has to expect that things will, most probably, not work the first time.”

“Every organization was built for a purpose. We haven’t built any organization just for the sake of its mere existence.”

“Never let something important become urgent.”

– Eliyahu M. Goldratt

Business Advice Quotes by Eliyahu M. Goldratt

“So this is the goal: To make money by increasing net profit, while simultaneously increasing return on investment, and simultaneously increasing cash flow.”

“In order to significantly increase sales, we have to increase the perception of the value of the market for our products.”

“Companies are so immersed in the mentality of saving money that they forget that the whole intention of a project is not to save money but to make money.”

“Inventory is all the money that the system has invested in purchasing things which it intends to sell.”

“Any money we’ve lost is the operational expense; any investment that we can sell is inventory.”

“Operational expense,” he says. “Operational expense is all the money the system spends in order to turn inventory into throughput.”

“Throughput is the rate at which the system generates money through sales.”

“If you produce something, but don’t sell it, it’s not throughput”

“Flow means that inventories in the operation are moving. When inventory is not moving, inventory accumulates. Accumulation of inventory takes up space. Therefore, an intuitive way to achieve better flow is to limit the space allowed for inventory to accumulate. To achieve better flow, Ford limited the space allotted for work-in-process between each two work centers.”

“Activating a resource is like pressing the ON switch of a machine; it runs whether or not there is any benefit to be derived from the work it’s doing.”

“I say an hour lost at a bottleneck is an hour out of the entire system. I say an hour saved at a non-bottleneck is worthless. Bottlenecks govern both throughput and inventory.”

“The goal is not to improve one measurement in isolation. The goal is to reduce operational expenses AND reduce inventories and increase throughput simultaneously.”

“They’re measurements which express the goal of making money perfectly well, but which also permit you to develop operational rules for running your plant,” he says. “There are three of them. Their names are throughput, inventory and operational expense.”

“Companies are so immersed in the mentality of saving money that they forget that the whole intention of a project is not to save money but to make money.”

– Eliyahu M. Goldratt

Leadership and Management Advice Quotes by Eliyahu M. Goldratt

“Activating a resource and utilizing a resource are not synonymous.”

“Cost Accounting is enemy number one of productivity.”

“Since the strength of the chain is determined by the weakest link, then the first step to improve an organization must be to identify the weakest link.”

“Then the contribution of any single person to the organization’s purpose is strongly dependent upon the performance of others.”

“Since the strength of the chain is determined by the weakest link, then the first step to improve an organization must be to identify the weakest link.”

“Fundamentally, a manager is looking to answer these questions: ‘what to change?’,’ what to change to?’ and ‘ how to cause the change?’”

“We had physical constraints that helped us to focus our attention, to zoom in on the real policy constraint.”

“If synchronized efforts are required and the contribution of one link is strongly dependent on the performance of the other links, we cannot ignore the fact that organizations are not just a pile of different links, they should be regarded as chains.”

Why not make the work easier and more interesting so that people do not have to sweat? The Toyota style is not to create results by working hard. It is a system that says there is no limit to people’s creativity. People don’t go to Toyota to ‘work’ they go there to ‘think.’”

“The minute you supply a person with the answers, by that very action you block them, once and for all, from the opportunity of inventing those same answers for themselves. If you want to go on an ego trip, to show how smart you are, give the answers. But if what you want is action to be taken, then you must refrain from giving the answers.”

“Cost Accounting is enemy number one of productivity.”

– Eliyahu M. Goldratt

Share these Insights to increase Your Influence

Share this page with your network to increase your Influence. Then explore the additional Coaching Information from some of the world’s top experts. Click the links below:

“What you’re saying is that making an employee work and profiting from that work are two different things.”

– Eliyahu M. Goldratt

Eliyahu M. Goldratt – Production Advice Quotes

“What you have learned is that the capacity of the plant is equal to the capacity of its bottlenecks.”

“The entire bottleneck concept is not geared to decrease operating expense, it’s focused on increasing throughput.”

“Local efficiencies must be abolished. A focusing process to balance flow must be in place.”

“The entire bottleneck concept is not geared to decrease operating expense, it’s focused on increasing throughput.”

“Kanban system directs each work center when and what to produce but, more importantly, it directs when not to produce. No card—no production.”

“A balanced plant is essentially what every manufacturing manager in the whole western world has struggled to achieve. It’s a plant where the capacity of each and every resource is balanced exactly with demand from the market.”

“Make the bottlenecks work only on what will contribute to throughput today … not nine months from now. That’s one way to increase capacity at the bottlenecks. The other way you increase bottleneck capacity is to take some of the load off the bottlenecks and give it to non-bottlenecks.”

“The entire bottleneck concept is not geared to decrease operating expense, it’s focused on increasing throughput.”

– Eliyahu M. Goldratt

Eliyahu M. Goldratt Inspirational Quotes

“If you don’t manufacture a quality product all you’ve got at the end is a bunch of expensive mistakes.”

“Common sense is not so common and is the highest praise we give to a chain of logical conclusions.”

“An expert is not someone who gives you the answer, it is someone who asks you the right question.”

“All those calls and meetings were fire fighting.”

“What I’m telling you is, productivity is meaningless unless you know what your goal is.”

“Every action that brings a company closer to its goal is productive.”

“Science is simply the method we use to try and postulate a minimum set of assumptions that can explain, through a straightforward logical derivation, the existence of many phenomena of nature.”

“If we reduce batch sizes by half, we also reduce by half the time it will take to process a batch. That means we reduce queue and wait by half as well. Reduce those by half, and we reduce by about half the total time parts spend in the plant. Reduce the time parts spend in the plant and our total lead time condenses. And with faster turn-around on orders, customers get their orders faster.”

“Since the strength of the chain is determined by the weakest link, then the first step to improve an organization must be to identify the weakest link.”

– Eliyahu M. Goldratt

Mini MBA of the Big Ideas that have shaped Careers, Leadership, and Business.

“Strategies for Influence” explores and shares the BIG IDEAS from the Leaders of Influence that can help you with your Career, Business, and Leadership. Click on any of the links below for a Min-MBA on the Big Ideas that have influenced our work and culture.

“Somewhere in the scientific method lies the answer for the needed management techniques. It is obvious.”

– Eliyahu M. Goldratt

Books by Eliyahu M. Goldratt

- The Goal, by Eliyahu M. Goldratt, 1984

- It’s Not Luck, by Eliyahu M. Goldratt, 1994

- Critical Chain, by Eliyahu M. Goldratt, 1997

- The Choice, by Eliyahu M. Goldratt, 2008

- Necessary But Not Sufficient, by Eliyahu M. Goldratt, 2000

- The Goal: A Business Graphic Novel, by Dwight Jon Zimmerman and Eliyahu M. Goldratt, 2017

- Beyond the Goal: Eliyahu Goldratt Speaks on the Theory of Constraints, by Eliyahu M. Goldratt, 2005

- The Race, by Eliyahu M. Goldratt, 2008

- Project Management the TOC Way, by Eliyahu M. Goldratt, 1996

- What is This Thing Called Theory of Constraints and how Should it be Implemented? by Eliyahu M. Goldratt, 1990

- Essays on the Theory of Constraints, by Eliyahu M. Goldratt, 1998

- Late Night Discussions on the Theory of Constraints, by Eliyahu M. Goldratt, 1992

- Introduction to TOC-My Perspective, by Eliyahu M. Goldratt, 2010

- The Haystack Syndrome, by Eliyahu M. Goldratt, 1990

- Reaching the Goal: How Managers Improve a Services Business Using Goldratt’s Theory of Constraints, by John Arthur Ricketts, 2007

Books about Theory of Constraints (TOC)

- Theory of Constraints Handbook, by John G. Schleier, 2010

- The Logical Thinking Process: A Systems Approach to Complex Problem Solving, by H. Dettmer, 2007

- Thinking for a Change: Putting the TOC Thinking Processes to Use, by Lisa J. Scheinkopf, 1999

- Project Management in the Fast Lane: Applying the Theory of Constraints, by Robert C. Newbold, 1998

- Manufacturer’s Guide to Implementing the Theory of Constraints, by Mark Woeppel, 2000

- Goldratt’s Theory of Constraints, by H. Dettmer, 1997

- The Ultimate Improvement Cycle: Maximizing Profits Through the Integration of Lean, Six Sigma, and the Theory of Constraints, by Robert F. Sproull, 2009

- Strategic Navigation: A Systems Approach to Business Strategy, by H. Dettmer, 2003

- Manufacturing at Warp Speed: Optimizing Supply Chain Financial Performance, by Eli Schragenheim and H. Dettmer, 2000

- The World of the Theory of Constraints: A Review of the International Literature, by Steven J Balderstone and Victoria J Mabin, 2000

- Introduction to the Theory of Constraints (TOC) Management System, by Thomas B. McMullen, 1998

- Velocity: Combining Lean, Six Sigma and the Theory of Constraints to Achieve Breakthrough Performance – A Business Novel, by Dee Jacob, Suzan Bergland, Jeff Cox, 2015

- Management Dilemmas: The Theory of Constraints Approach to Problem Identification and Solutions, by Eli Schragenheim, 1998

- Deming and Goldratt: The Theory of Constraints and the System of Profound Knowledge, by Domenico Lepore and Oded Cohen, 1999

- Epiphanized: Integrating Theory of Constraints, Lean and Six Sigma (TLS), by Bob Fox, Bruce Jay Nelson, and Robert F. Sproull, 2012

Questions about Eliyahu M. Goldratt

“What I’m telling you is, productivity is meaningless unless you know what your goal is,”

– Eliyahu M. Goldratt

Eliyahu M. Goldratt– Videos

Basics of Theory of Constraints

Providing the answer to “What to change?”

“An expert is not someone who gives you the answer, it is someone who asks you the right question.”

– Eliyahu M. Goldratt

Image Credit: Image by Rudy and Peter Skitterians from Pixabay

You must be logged in to post a comment.